Management Team

History of Gearloose

-

1997

Initially, laps were cast from 95/5 tin/antimony solder for my use in the shop. This was a good alloy, and being lead-free, this solder alloy was NSF Approved for drinking water use. Other tin/antimony alloys used in faceting were the 92/8 pewter series. I personally have reservations about foundry practices involving alloys containing this much antimony, and made a series of changes to alloy compositions using nontoxic substitutions. BATT™ alloy and casting methods were developed to create a “Cored” structure that held diamonds well. Such castings are generally useless for structural applications, but here we finally had an alloy that was specificaly developed for lapidary use.

Why BATT Takes Up and Holds Diamonds:

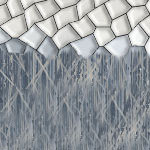

People have often commented on BATT™ absorbing a lot of diamond into its structure. Its crystal structure is grown columnar, like the grain in wood in a slice of a tree log. When you charge a BATT™, the diamond enters the “End Grain”, typically to a depth of >.1 mm..

-

2000

Suppose we took a copper lap, which when charged with 3K was a fast prepolisher, and cast and bonded a BATT™ 6″ disk in the center, for use with 50K or 100K diamond. We could prepolish and polish on the same lap with the same height adjustment in one operastion.

This lap was called the “Redwing”, and became hugely popular, despite its neccesary price. About 800 were sold.

-

2002

Tin prices doubled.

- Copper prices rose. This ended the Redwing™ lap. The price would have exceeded $200 for the product. Yes, some people would have paid it, because several production cutters relied on it. However, I am a gemcutter, and said to myself, “*I* would not pay that for a lap!!!

-

2005

BA5T™, finer grained alloy of higher hardness, and smoother “Feel” was introduced. This complex alloy was developed for production polishing. A heavier casting was needed to develop grain structure and allow a lifetime of resurfacings, and was a “Price is no object” product. Some of the alloying metals are sold by the Troy Ounce or by the Gram. The lap has it adherants, because of the superior polishing speeds and the quality of the finished facet, and continues to sell well to a small market within a small market. Between 5 and 6 hundred have been sold, and the product remains in production.

-

2006

Tin prices have tripled since the introduction of the BATT™ and the prices had to be raised to their current level, or production would have to cease. I had resisted this for over a year, but it became obvious tin prices were not going to go back down, and recently, it appears there is no end in sight for further increases. The Dollar is declining, also, so some tin price increases have been offset by export BATT™ sales, because now, they are CHEAP, if one has Euros. People from Europe are now flying to New York to shop, just as WE used to shop in Matamoros.

What a wonderful feeling.

-

2007

The original BATT™ formula had been tweaked and adjusted many times over the years to improve its properties, but in 2007 major changes were made by using other nontoxic and more effective hardners, grain refiners, and deoxidizers. Casting qualities were further improved, and the laps were easier to charge and wasted less dimaond in the process.

I introduced a laminated lap, in hopes of bringing back the days of “A Dollar an inch of diameter” pricing that had been a rule of thumb in the industry for decades. But because 4% of them had developed delamination problems, and the Accountant pointed out that the increased labor ate up all the metal savings, the product was nonviable, and was shut down quickly. I resolved to continue working to develop a lap that could be afforded by the Hobbyist.

-

2008

The experiments beginning in 2007 finally started the creation of a new affordable lap. I needed to reduce the alloy content, and make a structure that was friendlier to oxides. The first lap had been provisionally named the “DUKK™”, because it was amphibious, working well with both oils and water slurries. However, the feedback I have been getting from the testers so far is along the lines of, “It’s not a BATT™”. It’s not. So once again, I invented myself into a corner, because the BATT™ is the standard any new metal lap will be measured against.

The next step was to take some of the methods I used to develop the above lap, but to discard the process of a chargable metal composite lap. Though the metals markets are currently going down, we all have a bitter taste left of what the speculators and emerging economies have done to the prices. We needed something that would avoid the charging techniques that some users had trouble mastering. Many of the old composition laps like phenolic were foolproof and polished acceptable facets, but did so at the cost of frictional heating. So, incorporating the lubricity with tin alloys as a start, a polymer composite was developed that had low frictional coefficient, accepted water based or oil-based polishes (Something the “DUKK” anticipated) and by getting away from the metals price gouging, finally produce a more affordable lap. Last Summer I started sending out samples to commercial cutters, and people have been very pleased with the new “DARKSIDE™”

Here it is:

-

2009

Now that we have done THAT, and the Darkside™ has been so well accepted, it was possible to bring back the concept of the Redwing™!

Now again, people can prepolish with 3K diamond on the outer ring, then, wipe the stone and jump into the center section and polish on the Darkside zone with their choice of polish. As with the redwing™, this mean no lap change, no height adjustment, and no cheater notes. The BATTWING was introduced June 1, 2009.

Also, in 2009, the BATTSTIK and the DIASTIK were introduced. The BATTSTIK is an oxide polish in a water-soluble wax-like matrix, which friction melts when applied to the spinning lap. This product has been accepted and is an ongoing success, technically. Business-wise, it is not, because they last so long, people seldom need to reorder them. They are available in Cerium Oxide, Chrome Oxide, and Alumina. They were originally developed to train people to STOP using too much oxide polish on the Darksides™.

Most of the polishes we buy end up lining the splash bowl. The experience with the BATTSTIK™ led to the development of its diamond-based version, the DIASTIK™. The DIASTIK™ likewise trains people to use the “Monolayer” concept for the correct amount of polish application. It’s concept is a little more complex than that of the BATTSTIKs™, in that there are multiphase lubricants, dispersants, and coolants involved. They have been found to be effective on ceramic laps as well, because the most common error in using these is poor control of diamond film thickness.

Both the “STIK” products are formulated from hypoallergenic, nontoxic, FDA FD&C listed compounds.

NOW: What to do about cleaning and additional lubrication?

After considerable effort, a new cleaner and lap lubricant was developed. originally named “BATTGLIDE”. This avoided the skin-drying petrochemicals and their odors, associated with products like WD-40™, which did a good job, but had these drawbacks. I got emails from people who mocked the name, and was refered to some products that were used as pesonal lubricants, and worse. I can take a joke.

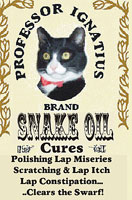

So..someone suggested “Snake Oil”, I did a quick survey, and people liked the name. I named it after my Cat Friend..Let’s see them make a dirty joke about THAT!

Also, in 2009, Gearloose.com d/b/a was incorporated as “Gearloose Lapidary, LLC”. 2010: The Greenway™ lap was introduced in March, 2010. A highly loaded chrome oxide composite with antifriction additives for cooler running, it is, like products made with Cerium and Aluminum oxides that have been around for years, a “Just Add Water” lap. The Chrome Oxide BATTSTIK™ was successful at getting people to try Chrome Oxide on Darkside™, as it reduced the green mess. Visitors to Brazil often comment on the “Green shops”, as Chrome Oxide powder ends up everywhere. It is a wonderful, agressive polish for the quartzes, and unlike cerium oxide, which is specific for quartz and a few other stones, chrome oxide polishes the beryls, feldspars, spodumenes, tourmalines, tanzanite, and topaz.

-

2010

NEW! The GREENWAY™ Chrome Oxide Composite Lap.

In September 2010, the GREENWING™ was released. This is a version of the BATTWING™ that has a Greenway center polishing section. The GREENWING needs only a 3K Diastik™ and water, to take a stone from #600 cutting though 3K prepolish and polishing, in one lap change. This is a successful product with many good reviews.

-

2011

The Fourteenth year was very eventful. The most significant event was the 58% increase in Tin Prices, for no particualr reason, other than the vermin who gave us the Subprime crisis moving into commodities. Warehouse volumes were high-There were no real shortages.

I examined the history and popularity of cast zinc laps in order to offer my customers more choices.

There were surprises. I never cared for them very much, though many Old Pros liked them for sapphire polishing. One thing I dscovered is that no one ever really used a zinc lap. The “Zinc” laps that had been made were really the almuminum-containg ZAMAC alloys, so in some countries, the castings were old carbureters and hard drives thrown into a melting pot by unfortunates.

A new zinc alloy was designed the right way, with ISO-900x vendors with ASME specifications and certified levels of lead and cadmium.

Surprise! These laps made the fastest, smoothest prepolishing laps, in particular. 3K diamond was actaully too FAST, and people were going by the meets all the time!

A 8K DIASTIK was put into production immediately.

A “Wing” version of the lap, called the “Xinquing” opened to standing ovations. They are available in either Darkside™ or GREENWAY™ Polishing centers.

Also. on request, I produced a reissue of the “Redwing on Steroids”, called the “Redwing Plus 5″. Made of solid cpper, and with a polishing center zone of BA5T™ despite their neccesarily high cost, several production batches were sold out in advance.

-

2013: A creative explosion of product development:

Thomas Smith at Adamas Instrument Corporation is a colored stone and diamond cutter. A major part of his business was diamond opthalmic blades. Diamond cutting can be tedious, and Tom had years to sit there and THINK. And think.

He contacted me, we were talking, and he mentioned a “Magic Bullet” for quartzes he had been using for some time.

“Stop..don’t tell me anything without some kind of agreement”. ( We do not need to steal ideas here.)

He had some ideas, we had a running factory with many processes in place. Perfect.

Thus began the Creamway™ lap, and the Zirconia BATTSTIK™, which have essentially obsoleted cerium oxide.

Why? Because few years ago, China disrupted the Rare Earth Metals markets, and suddenly people were desperate for cerium oxide (And lanthanum, neodymium, and samarium).

This was a wonderful opportunity to say “Shove it” to commodities manipulators. May it happen often.

Then came the Skyway™ lap, a more aggressive version of Creamway™.

Next came the MATRIX™, the ceramic/polymer composite polishing lap with the highest surface complexity ever manufactured (FD=1.897+). This is a big hit, a tremendously versatile polishing lap, useful with oxides or diamond.

The MATRIX™ was further optimized for diamond-toughened and hardened for flatter facets and higher surface charging. This lap became the DiaMatrix™ and was an instant hit with moissanite cutters (And sapphire, and CZ and Topaz and, and…) The first sales were 10″ laps for automated production machines.

Now..Since the Diamatrix™ has proven itself as being so versatile and effective, and the BATT™ with 3K diamond has dominated prepolishing, suppose a “Wing” type lap is made. And called the (haha) DOMINATRIX™?

Big hit.

So big the old BATTWING™, GREENWING, and XINQUING series is discontinued. There are commercial cutters who now use nothing but the Dominatrx™ for prepolishing and polishing.

Then: Let’s make a permanent prepolish lap, with SIX TIMES the diamond concentration of anything on the gemcutting market! The TWISTOR™.

The first sales of this lap were 10″ sizes used on robotic cutters, it was a natural, because the lap only needed a water drip, and no baby-sitting. This meant the production houses could run many robotic cutters, simultaneously. $$$$!

Now, as of May 19, it is still going on, with the DiaTwist™, a “Wing” lap with Twistor™ prepolish on the outer band, and DiaMatrix on the center polishing zone.

Go back and read the lapidary magazines from the 1970’s. Often you will still see some of those products being sold today.

Our mission is to remain forty years ahead.